Reasons To Prefer Copper Wiring Instead of Aluminium Wires in Households

Posted on Jul 19, 2018

In 1960’s Aluminum was predominantly used in household wiring due to the rise in the cost of Copper wires. A belief existed that aluminum wire required larger wire gauge as compared to copper in carrying same amount of current, which resulted in failure. The improper connection techniques and use of dissimilar materials generated heat as they could not bear the electrical load and also caused overheated connections.

History of Aluminum Wire

Aluminum wire was extensively used to transmit electricity from utility generating stations to individual meters as it takes half amount of aluminum wire than copper to carry equal current and also half supporting structures are required for transmission lines with this lightweight conductor. AA-8000 series is the advanced technological aluminum wire for branch circuitry; though rarely used, on proper installation it is as safe as copper wire.

Disadvantage of Aluminum wires

Aluminum wire with improper connections often led to failures which resulted in house fire which took many lives. The two probable reasons of failure are: poor workmanship and difference in coefficient of expansion in aluminum wire and the terminator used in 1960’s. Feeder and branch circuit wiring system were designed according to copper conductors, as the price of copper was high that time; aluminum wiring was extensively used for installation as an alternate to copper. Due to the frequent installation of aluminum wire, industry suggested improvement in means of connection and terminating the use of smaller aluminum wire.

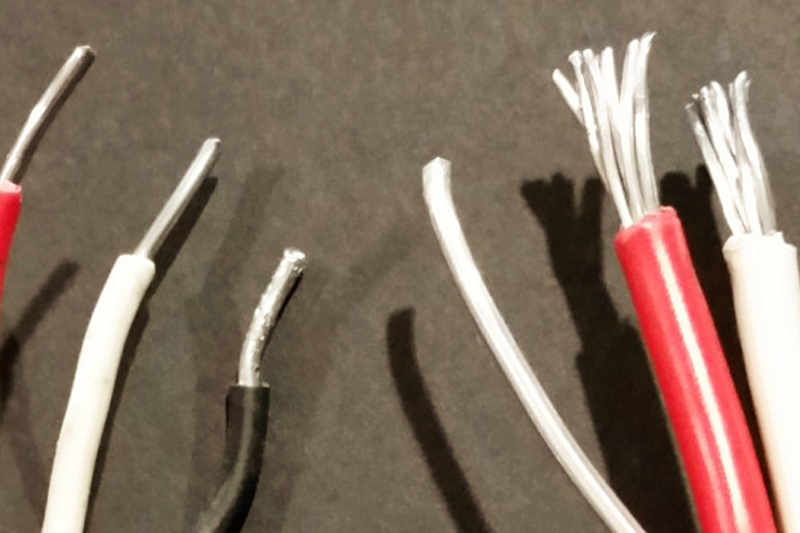

Improper installation involves – Improper tightened connections, wrong wrapping of wires around the binding screws, and aluminum conductors used in push-back connections which was designed for copper. Due to these incorrect connections, series of event failures originated. The connections were loose due to improper tightening; as steel screws were used instead of brass on receptacles, aluminum and steel having different rate of expansion increased the temperature and resistance at termination point; same problems erupted when aluminum conductors were used in place of copper wire in push-in connections.

National Bureau of Standards’ study reveals that alloys of steel and aluminum resulted in high resistance termination and not corrosion and when a thin layer of oxide is applied on aluminum conductor it does not corrode. Bare Aluminum Wire can be hazardous for household as they have high possibility of overheating in comparison to copper wires.

Remodeling Aluminum wired household

Several up gradation to homes before 1974 having aluminum branch circuit wiring are:

• The devices have been rated for aluminum wire usage, those who are not do not meet designated specification

• Splicing of short length copper wire to main aluminum wire for use do not comply with laid out specifications

• Creating cold weld between copper and aluminum wire are considered permanent and maintenance free repair and large enclosures are installed for fitting existing enclosures.

• Rewiring entirely with copper

A qualified professional should be hired for any electrical installation or replacement. In every 10 years do evaluate electrical system to determine its safety under increased loads.